Structuring and coding with ISO / IEC-81346

06 March 2020

When people want to discuss technical systems in practice, confusion often arises, due to no common terminology and language that is being used. The ISO / IEC 81346 standard has been developed to prevent this miscommunication. This standard provides tools for structuring, coding and referring to complex mechatronic systems over the entire life cycle of these systems.

.

What is ISO / IEC-81346?

The ISO / IEC 81346 standard describes a method that helps to refer to complex technical systems. It uses several concepts:

- Structuring systems and objects

- Structuring systems from different aspects

- Coding systems according to internationally agreed tables

This standard is often applied in large international projects. In these types of projects, there is often a high need for a common language. Yet, this method can also be of great use for machine builders, system integrators and end-users.

.

What is a tag code and what is it used for?

The use of tag coding is already known in different industries. These codes can often be found in various documents such as a P&ID, machine layout and instrumentation lists. The purpose of a tag code is to be able to refer to a specific object that occurs in 1 or more documents. Many of these tag codes have a fixed structure in which certain parts of the code have a certain meaning. The tag code can also cause a lot of disagreements, as the coding is often constructed from different perspectives.

A programmer would prefer to build coding from a functional perspective, whereas an electrical engineer is more likely to build a structure from a product or location perspective. It also regularly happens that an end-user shares a different viewpoint as compared to, for example, a machine builder.

So, who is leading at determining this one code?

.

Why ISO / IEC-81346?

The ISO / IEC-81346 describes the use of reference codes. This is comparable to tag coding but there is 1 fundamental difference; there can be several codes that refer to the same object. This may seem pointless at first, but it certainly isn’t.

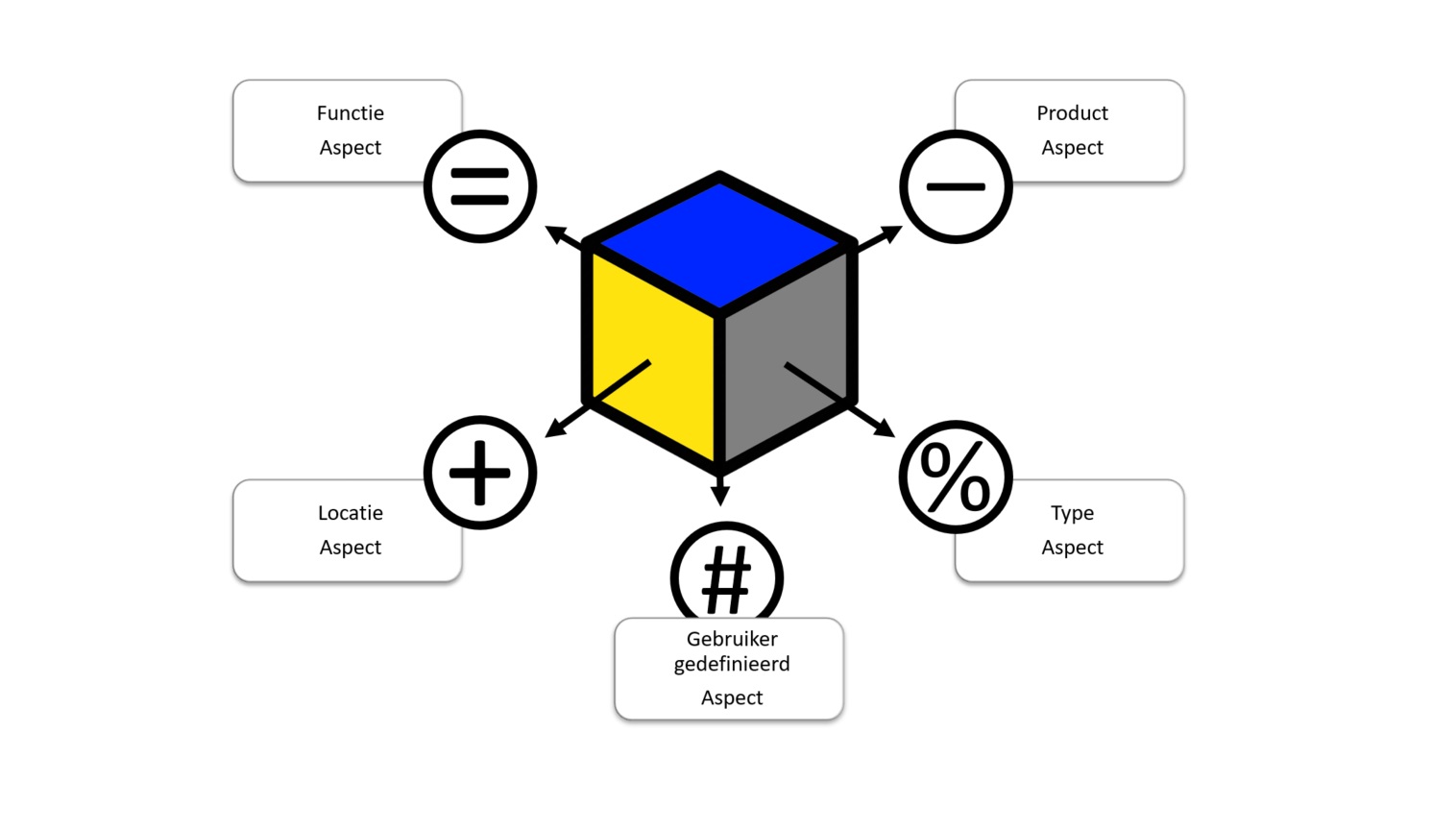

The standard introduces several standard aspects, each with its own prefix character:

= Function aspect

– Product aspect

+ Location aspect

% Type of aspect

When we look at 1 aspect of a system, there is often little discussion about the structure of that aspect. Allowing multiple structures to exist creates interesting opportunities.

We could answer questions such as:

Which (-) products must be mounted on (+) location1?

Which (%) type of products can we use to fulfil a (=) function?

Which connections (e.g. cables) are there between (+) Location1 and (+) Location2?

In this way, opportunities arise to filter, group and refer to documents. Therefore, very powerful data for the different phases of a system life-cycle is generated. In combination with documentation standards such as IEC-61355, a coherent set of documents is created that fully describes the systems.

Are you wondering how this standard can help you with the day-to-day complexity of your projects and systems?

We regularly organize knowledge-sharing events at Yellax in which one of our technical consultants will explain and discuss this standard in detail together.

.

Please keep an eye on our events page!